Production process

1. Receiving technical documentation from the client/foundry.

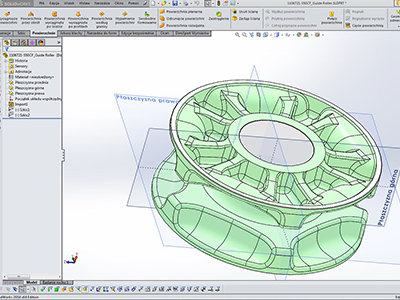

2. In the absence of a 3D drawing, creation of spatial geometry.

3. Analysis of the technical drawing (proposal of own technological solutions)

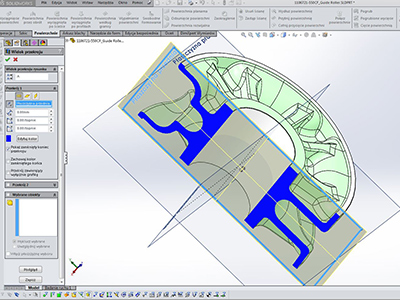

4. Designing the model and core boxes’ construction.

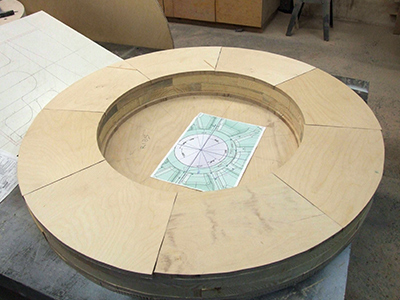

5. Choosing the material depending on the amount of moulds and requirements set by the client.

6. Material bonding.

7. Computer-based CAM preparations, CNC machine milling.

8. Assembly of the model set by professional casting modellers.

9. Creation of interlope measuring sheet in the course of assembling the respective components

10. Preliminary painting with putty spraying machine.

cleaning and refilling of cavities with high-quality filler,

cleaning till surface smoothness is achieved,

application of a second layer of putty spray

cleaning with 120 -150 paper and surface preparation for painting,

Final painting with a two-component polyurethane paint

10.Dimensioning of the complete model set – creation of a measuring sheet,

11. Packaging and shipping of the model set.

Biuro Technicast

ul. Czysta 32, Piotrków Trybunalski

NIP: 771-115-85-90

Zakład produkcyjny

ul. W. Polskiego 108/112,

Piotrków Trybunalski

Kontakt

technicast@o2.pl

tel. +48 44 648 49 60

kom. +48 885 915 455